Transforming Surfaces with Precision & Power

Efficiently Removes Paint & Rust

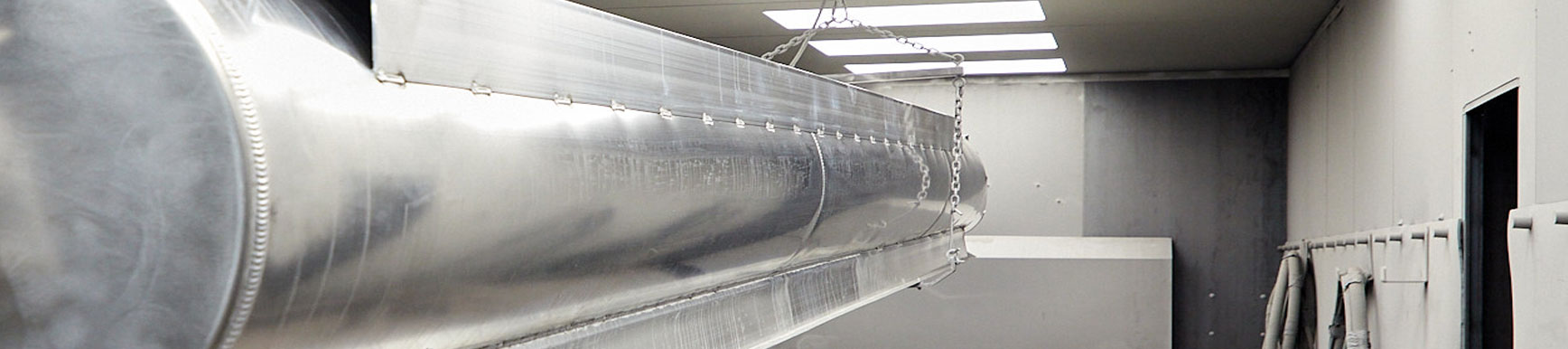

When powder coating, it is very important that the item you are coating is completely clean of oils, dirt, paint, oxidation, corrosion and damaged plating or other coatings. All of these things can interfere with the powder coating process causing imperfections in the finish or causing it to fail completely. Media blasting efficiently and effectively removes old paint, rust, corrosion, oil and debris and creates a smooth, uniform surface that is ready for powder coating. All types of metal end up with a better powder coating finish if they have been media blasted.

What is Media Blasting?

The process of removing paint, rust, or other surface contaminants from metal surfaces is called blasting. In blasting, suction is created by compressed air or a liquid agent to move a media (water, soda, aluminum oxide, garnet, glass bead, etc.) across the surface of the metal to be coated.

Media blasting at Jensen Powder Finishers uses a media blast cabinet to apply high-pressure air and a dry media to break down the contaminants and remove them from the surface of the parts to be powder coated.

Capabilities

Get in touch

Call Us Today:

262-886-1212

The Benefits of Media Blasting:

Jensen Powder Finishers is dedicated to serving our clients with the highest level of craftsmanship and customer service. For all your powder coating requirements, trust us to deliver results that exceed expectations. Contact us today to discuss how we can support your next project with our exceptional powder coating capabilities.