More Information on Powder Coating

Better Than Traditional Paint

Powder coating provides a durable, dazzling finish that is resistant to chipping and fading. The electrostatic application process ensures even coverage and minimizes drips, runs and other imperfections that are associated with standard liquid paint. Powder coating processes are generally more efficient than the traditional painting processes, as they require fewer coats, less drying time and produce less waste. Powder coating produces a high-end product that customers have come to expect and is preferred finishing method for manufacturers of metal goods.

Powder Coating Steps:

- Surface Preparation: The surface to be coated is cleaned thoroughly to remove any dirt, oil, rust or other contaminants that could interfere with paint adhesion. This step may involve cleaning methods such as blasting, nanotechnology treatment or chemical cleaning.

- Powder Application: The cleaned surface is electrostatically charged and the powder coating material is applied using a spray gun or automatic spray system. The charged powder particles are attracted to the grounded surface, resulting in a uniform coating.

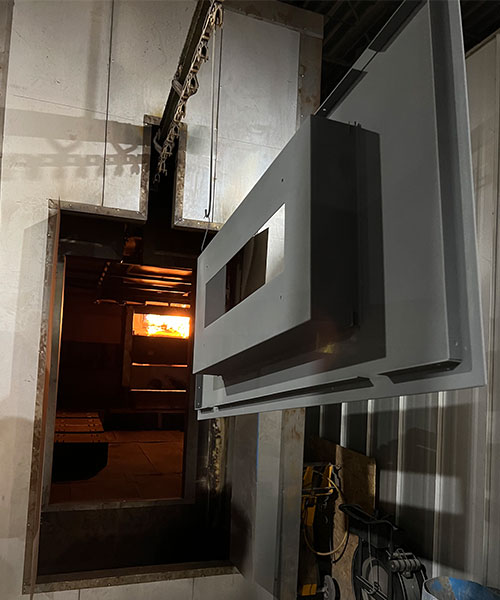

- Curing: After the powder is applied, the coated object is moved to a curing oven. The heat from the oven causes the powder particles to melt and fuse together, forming a smooth and continuous coating on the surface. The curing process typically takes place at temperatures ranging from 300°F to 450°F for 10 to 30 minutes, depending on the type of powder and the thickness of the coating.

- Cooling: Once the curing process is complete, the coated object is allowed to cool down to room temperature. During this cooling phase, the powder coating hardens and adheres firmly to the surface.

Powder Coating is:

About

get in touch

Call Us Today: 262-886-1212

Jensen Powder Finishers is dedicated to serving our clients with the highest level of craftsmanship and customer service. For all your powder coating requirements, trust us to deliver results that exceed expectations. Contact us today to discuss how we can support your next project with our exceptional powder coating capabilities.